|

| July 21, 2015 | Volume 11 Issue 27 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Product simplification: Rediscover a whole new game

By John Gilligan, President, Boothroyd Dewhurst, Inc.

John Gilligan, President, Boothroyd Dewhurst.

Product simplification is the discipline of merging the greatest performance functionality into the fewest number of parts using the most suitable and cost-effective materials and manufacturing processes. It is an engineering board game, in a way, answering questions about a design and seeing a Design for Manufacture and Assembly (DFMA) database respond with quantitative costs and reports. There is truth and mystery in confronting an analysis that says there are too many parts, shows the team where, and then launches everyone into the intimacy of trial-and-error engineering, collaboration, and splendid, fresh creation.

It's a game that companies would ideally play regularly, but tend to do most vigorously when innovation and efficiency are both in crisis. Needless to say, in our current economy, providing optimized cost and maximum performance of design are the manufacturing nation's strongest winning moves.

For more than 25 years, cross-functional product development teams have discovered and rediscovered the phenomenon of product simplification in meeting do-or-die cost targets for their companies. Along the path to creating best-cost products, manufacturers learned that it is through the rigorous combination of design and process innovation that market desirability and engineering elegance are achieved in tandem.

Yesterday's innovative design ideas and process choices are today's competitive standards. DFMA was a boon to the plastics industry in the late 1980s and '90s because plastics was one of the easiest and most adaptable materials for combining individual parts into multi-functional, single components that helped the product as a "system" of interdependent relationships. Snap fits and living-hinge techniques became great tactics for innovation by Dell, HP, and Motorola. These companies and many others redefined the use of plastics and sheet metal to lower assembly costs. Even screws, the most labor-intensive securing method, evolved to better compete against the plastics/ease-of-assembly revolution. Product simplification is the engine of change.

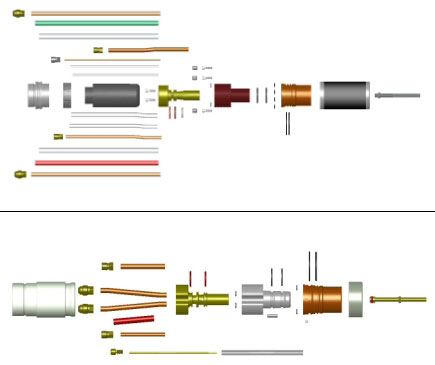

Hypertherm used DFMA software to analyze and simplify the design of a plasma cutting torch. An exploded model of the original torch assembly is shown at top. For the new torch design (below), Hypertherm engineers determined how to configure adjacent copper tubing without requiring Teflon insulating sleeves. They saved additional cost by eliminating a time-consuming potting process. Part count for the torch fell from 58 to 42. Assembly time dropped from 374 minutes to an astonishing 7 minutes.

Beyond plastics, engineers made other daring moves from the DFMA game board. Medical companies, such as Abbott Diagnostics and the former Ciba Corning, embedded hydraulics and printed circuits into structural supports for their blood gas analyzers to avoid individual part costs, potential part failures, and added assembly labor. Dell and HP continued their design assault on unnecessary cables, harnesses, and separate electronic components, building new functionality onto circuit boards.

The most radical and also immediate process advances will now come from laser sintering [a form of additive manufacturing/3D printing], which has a stunning ability to change the laws of traditional manufacturability. Further out, but not far away, the next generation of manufacturers will incorporate multi-property/multi-layer materials to increase functionality in the fewest parts, even changing the behavior of mechanical properties over varied thermal-stress-motion-time factors to deliver unique, tailored performance.

It's always fun to play with others. Product simplification was helped, of course, by creative supply chains. Finally seeing an opportunity to advance new technology, suppliers showed their OEM partners how to use process breakthroughs to put answers on a sometimes-blank worksheet. The best OEM supplier partnerships, such as those fostered by Dynisco and Hypertherm, also strive to preserve everyone's profit margins and closely examine process waste. A designer's habit, for example, of creating molded ribs for purely visual symmetry adds to the manufacturing cost of a component. The expertise of both parties working in transparent collaboration with a cost analysis tool has unlocked significant, generally overlooked savings. Product simplification is a catalyst for collaboration, inside and outside the company.

There are other catalysts for innovation as well. Motorola University in Asia teaches the integration of lean, Six Sigma, and DFMA to internal design teams, suppliers, and customers. They recognize the impact of product simplification on quality, performance, and profitability in electronic products. Motorola's benchmarks for cost reduction are impressive. Knowing that their approach is a business, not just a technology strategy, engineers sit in redesign sessions with unit heads and even with presidents, and they use a business score card to measure progress and institutionalize best practices.

Lean, Six Sigma, and DFMA work together because reducing part interfaces statistically lowers the opportunity for failure; lean manufacturing organically demands ease of assembly and part efficiency to reach its goals. Motorola knows this secret of integration and openly tries to tell everyone who will listen. Product simplification is a market imperative and a source of profits and name-brand quality.

Innovation driven by DFMA could also keep the best products manufactured in their home countries, anywhere that might take place -- so that exporting is based solely on excellence and global demand. Product simplification removes huge amounts of labor locked into designs. New Hampshire-based Hypertherm is the world leader in plasma metal-cutting technology. With a goal of innovation and efficiency, they redesigned half their products during a five-year period and realized a 600 percent increase in profits per square foot of factory floor space, a 75 percent improvement in service costs, and a 50 percent reduction in labor expenses. Hypertherm sells 50 percent or more of its finished products overseas.

[Editor's note: See the Hypertherm story on slicing 500 parts off its plasma cutter design here in Designfax and on redesigning its CNC (computed numerically controlled) plasma cutting system here].

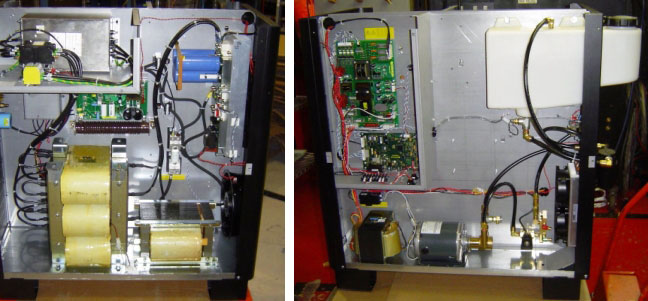

Before starting design work for the HPR130 plasma cutter power supply, Hypertherm benchmarked an existing power supply unit using DFMA methodology. This view shows only the left side of the HT2000 benchmark unit. It has 1,000 parts and was assembled from all four sides. Assembly time was 10 hours.

View of Hypertherm's redesigned HPR130 power supply. It has about 500 parts and is assembled from two sides -- in 63 percent less time. Hypertherm engineers improved assembly efficiency by incorporating mounting tabs and alignment features into the sheet metal structure, by simplifying cable connections, and by replacing dozens of wire connections with new printed circuit board designs.

The benefits of product simplification are spread through every "touch phase" of a product's travel -- from the napkin sketch idea, through CAD, production, shipping, administration, service, and end-of-life disposal. Innovation -- brought about through analytical costing and simplification of the complete product, from initial design to final disposal -- is the future. Wonderfully, the best industry innovators have already embraced a full understanding of the dynamic beauty of simplicity, but everyone can -- and should -- play this game.

Published August 2015

Rate this article

View our terms of use and privacy policy